Are you looking to boost your manufacturing process with high-performance materials? Thermoplastic...

What is Thermoplastic?

Thermoplastic sheets have become an indispensable part of the manufacturing industry, offering many benefits and applications. Thermoplastic, a versatile and easily moldable material, is gaining popularity due to its exceptional durability, flexibility, and cost-effectiveness.

From its ability to withstand extreme temperatures to its recyclability, join us as we uncover the ins and outs of thermoplastic sheets and why they are revolutionizing the field of manufacturing.

WHAT IS THERMOPLASTIC?

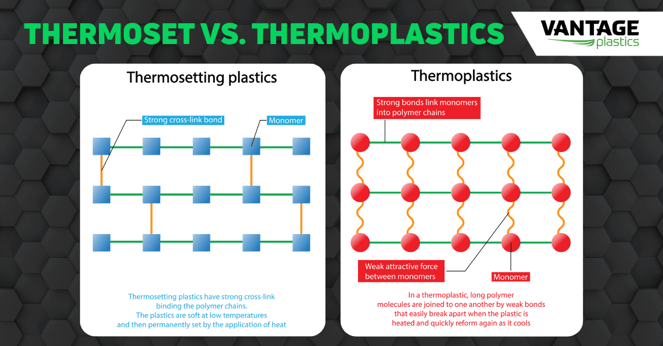

Thermoplastics are a class of polymer materials that can soften and become pliable when heated, allowing them to be easily molded into various shapes and forms. Unlike thermoset plastics, which permanently harden upon curing, thermoplastics can be melted and reformed multiple times without undergoing any significant chemical change.

Numerous types of thermoplastics are available, each with its own distinct properties and characteristics. Some common types of thermoplastics include:

- Polyethylene (PE)

- Polypropylene (PP)

- Polyvinyl Chloride (PVC)

- Polystyrene (PS)

- Acrylonitrile Butadiene Styrene (ABS)

THE BENEFITS OF MANUFACTURING THERMOPLASTIC SHEETS

Thermoplastic sheets are utilized in various industries due to their numerous benefits. From cost-effectiveness to sustainability, these sheets offer advantages that make them a popular choice for manufacturing applications.

COST-EFFECTIVENESS OF THERMOPLASTIC SHEETS

When it comes to manufacturing, cost is a crucial factor. Thermoplastic sheets provide a cost-effective solution compared to other materials. They are manufactured through an efficient and streamlined process, reducing production costs. Additionally, thermoplastic sheets can be easily molded and shaped, minimizing waste and optimizing material usage.

VERSATILITY AND DESIGN FLEXIBILITY

Thermoplastic sheets can be customized to meet specific requirements, allowing manufacturers to create complex and intricate designs. Whether creating unique shapes or incorporating intricate patterns, thermoplastic sheets offer a surplus of possibilities for design innovation.

LIGHTWEIGHT AND DURABLE

Thermoplastic sheets are known for their lightweight nature without compromising durability. This combination makes them ideal for applications where weight reduction is crucial, such as in aerospace or automotive industries. Despite their lightweight composition, thermoplastic sheets exhibit excellent strength and impact resistance, ensuring longevity and reliability.

RESISTANCE TO CHEMICALS AND CORROSION

Thermoplastic sheets demonstrate exceptional resistance to various chemicals, acids, and corrosive substances. This makes them suitable for use in environments where exposure to harsh chemicals is a concern, such as chemical processing plants or laboratory settings.

ENVIRONMENTAL SUSTAINABILITY OF THERMOPLASTIC SHEETS

In an increasingly eco-conscious world, sustainability is a key factor to consider in manufacturing processes. Thermoplastic sheets offer environmental benefits due to their recyclability and low energy consumption during production. Unlike other materials that degrade over time, thermoplastic sheets can be melted down and reused, reducing waste and minimizing environmental impact.

COMMON THERMOPLASTIC SHEET APPLICATIONS AND INDUSTRIES

Thermoplastics have gained immense popularity in various fields due to their unique properties and versatile nature. Let’s explore some common applications and industries that extensively utilize thermoplastic materials.

- Automotive Industry: In the automotive industry, manufacturers use thermoplastics for various applications, such as interior and exterior components, under-the-hood parts, electrical connectors, and fuel system components. Their lightweight nature, durability, and resistance to chemicals, heat, and impact make them an excellent choice for these applications. The automotive industry is also a significant user of thermoplastic reusable packaging.

- Packaging Industry: The packaging industry relies heavily on thermoplastics for manufacturing bottles, containers, films, and other packaging materials. Thermoplastic packaging materials offer good barrier properties, ensuring product safety and prolonging shelf life. Whether it’s food, pharmaceuticals, or consumer goods, thermoplastics provide a versatile and sustainable solution for packaging needs.

- Construction and Building Materials: Thermoplastic materials have found their way into the construction industry, used for applications such as pipes, fittings, insulation materials, and windows. The durability, weather resistance, and ease of installation make thermoplastics a preferred choice for these applications.

- Medical and Healthcare Industries: In medical and healthcare industries, thermoplastics play a vital role in producing medical devices, surgical instruments, drug delivery systems, prosthetics, etc. Thermoplastics offer biocompatibility, chemical resistance, moldability, and ease of sterilization.

- Consumer Goods and Appliances: Thermoplastics are extensively utilized in the production of consumer goods and appliances. From household items like kitchenware, toys, and cosmetic packaging to large appliances such as refrigerators and washing machines, thermoplastics offer versatility, aesthetics, and durability for plastic processes.

TAILORED THERMOPLASTIC SHEETS TO MEET YOUR UNIQUE SPECIFICATIONS WITH AIRPARK PLASTICS

Our facility boasts five extrusion lines, producing over 75,000,000 lbs. of custom thermoplastic sheet stock annually. Even better, we can elevate your sheets even further with our co-extrusion capability. This innovative process utilizes multiple extruders to create sheets with multiple color layers, diverse additives throughout, or different material mixtures (even incorporating recycled materials to save costs). Contact AirPark Plastics, a member of the Vantage Plastics family of companies, to learn more and to discuss your project needs.