Sustainable & Recyclable Materials

Advanced Sustainability and Recyclability

Vantage Plastics expertly crafts customer solutions using a range of materials, from commodity to proprietary blends, continually advancing our thermoforming expertise to lead industry innovation. Our manufacturing leverages these diverse materials for optimal product quality and functionality.

Our products can be made-to-order in any color you like or with stripes of color to help improve visibility.

Thermoforming Plastics

Shaping Innovation: Unveiling the Diversity of Thermoforming Plastics

Some of the thermoforming materials we commonly use in our manufacturing processes include the following:

- HDPE (High Density Polyethylene)

- HMWPE (High Molecular Weight Polyethylene)

- ABS (Acrylonitrile-Butadiene-Styrene)

- TPU (Thermoplastic Urethane)

- TPO (Thermoplastic Polyolefin)

- PS (Polystyrene)

- PC (Polycarbonate)

- PMMA (Polymethyl-methacrylate) (Acrylic)

Injection Molded Plastics

Plastic Exploration: Versatility in Injection Molded Materials

Some of the injection molding materials we commonly use in our manufacturing processes include the following:

- Acrylonitrile Butadiene Styrene (ABS)

- Polyethylene (PE)

- Nylon (Polyamide, PA)

- Polycarbonate (PC)

- Polypropylene (PP)

- Polyoxymethylene (POM)

- Thermoplastic Elastomer (TPE)

- Thermoplastic Polyurethane (TPU)

Proprietary Solutions

At Vantage Plastics, we harness the power of extrusion and forming techniques to enhance material characteristics or optimize costs. Our innovative approach includes integrating additives like Carbon Fiber for strength, Calcium Carbonate for durability, Talc for fire retardancy, and CS-320 for conductivity, further demonstrating our commitment to innovatively responsible solutions in thermoforming. Here are a few of the solutions that you can only find at Vantage Plastics and Lotis Technologies.

VanTech

Introducing VanTech, Vantage Plastics' exclusive proprietary material, designed to elevate the functionality of our existing material range. VanTech 80, with its anti-chafing properties, and VanTech 20, offering anti-skid benefits, are engineered to safeguard sensitive products during transit and handling, unlocking significant long-term cost savings for our customers.

VanStack

Discover Vantage Plastics' VanStack: our innovative solution for maximizing packaging density. VanStack boosts parts per unit, enhancing load efficiency and space utilization, leading to significant cost savings and a notable reduction in raw material usage. Embrace a smarter, more sustainable packaging approach with VanStack, designed for the modern, eco-conscious business.

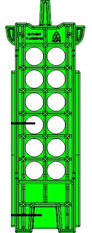

VanPack

Vantage Plastics' VanPack system is a cutting-edge, eco-friendly packaging solution that utilizes thermoformed HDPE for robust protection. It features an innovative peanut lock system for enhanced security and stackability, reducing the need for additional wrapping materials. Designed for longevity and convenience, VanPack streamlines the logistics process, being ISPM 15 exempt, and supports a greener footprint with its pallet buy-back initiative.