Explore Our Patented Exclusive Products

INNOVATIONS

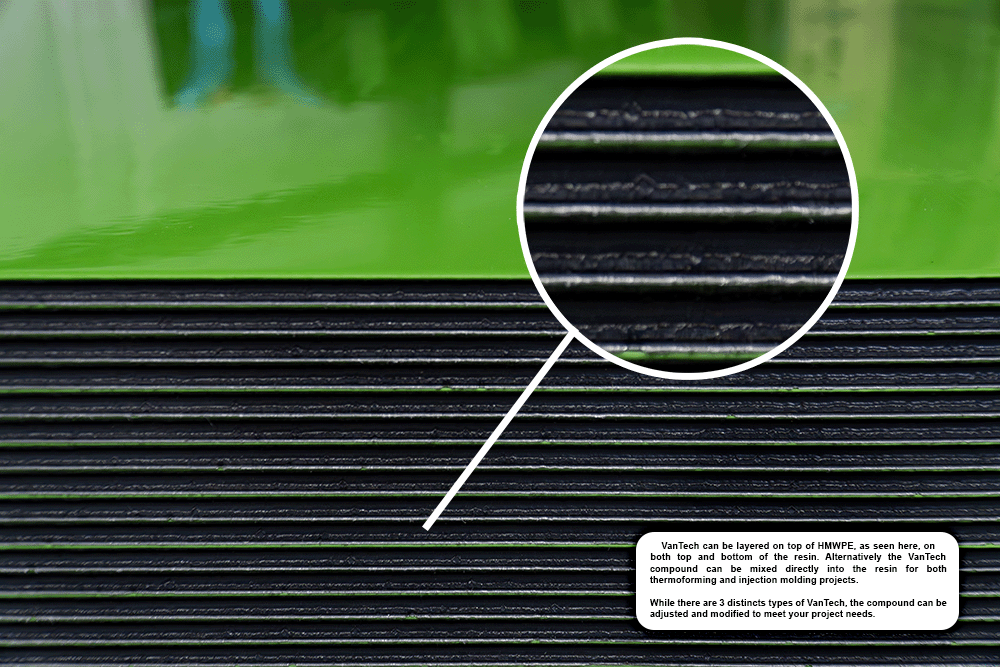

VanTech

A patented customizable compounding solution exclusive to Vantage Plastics.

Feature Benefits:

- Superior durability

- Enhanced longevity

- Exceptional abrasion resistance

- Extended wear life

- Smooth-gliding

- Reduced surface resistance

- Scuff-proof technology

- Anti-wear protection

- Dunnage weight reduction

- Temperature & shape deformity resistance

- Enhanced recyclability

Available for both Thermoforming & Injection Molding

Comparative Results vs. TPU

- Prevents Flaking Better – VanTech outperforms TPU in the amount of material rubbed off during testing.

- Lower density – reduces weight by 25%.

- Costs less – Based on current pricing VanTech is almost 30% less per pound.

- Assembly Savings – Both tooling and part assembly are cheaper.

- Recyclable – Trays using VanTech do not require disassembly before recycling.

- Improves Properties of Regrind – VanTech improves the impact properties and melt strength of the regrind.

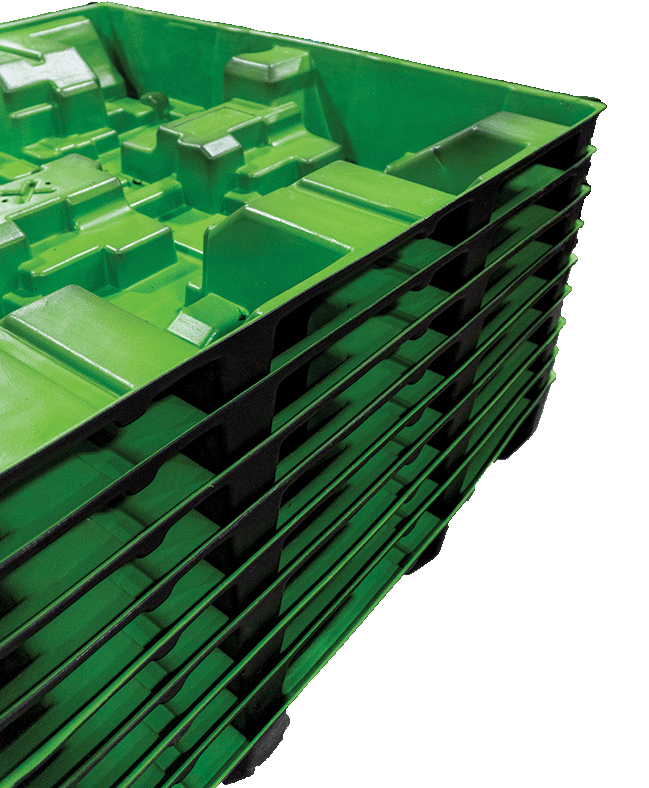

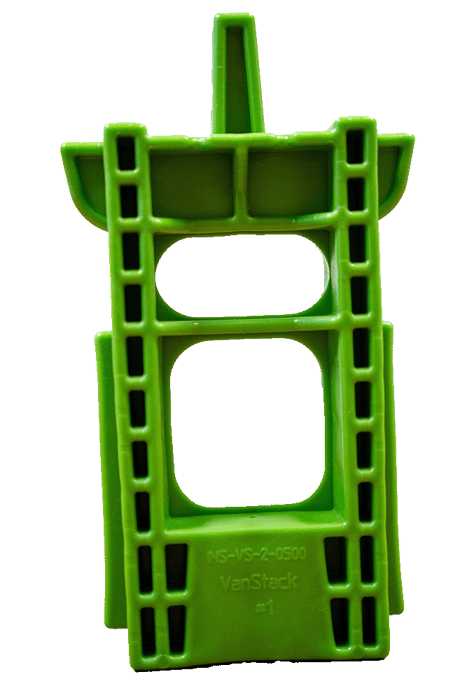

VanStack

An award winning, patented, load bearing, density increasing, cost saving dunnage solution that can be customized for your needs.

Benefits:

• Increased packaged parts per tray.

• Tray fleet size reduction.

• Reduction in trucks needed to ship.

• Reduction in tray weight.

• Ergonomic improvements.

• Reduction total material needed.

• VanStack columns are recyclable with

the tray at the end of the tray's life.

• Formed into the geometry of the tray.

• No fasteners or adhesive required.

Comparative Testing

The weight of the packaging is transferred through the VanStack columns rather than the thermoformed geometry.

- 28% Unit load density increase

- 42% Material starting thickness reduction

- 45% Tested load capacity increase

*Comparison of Ford packaging: existing design vs. VanStack design

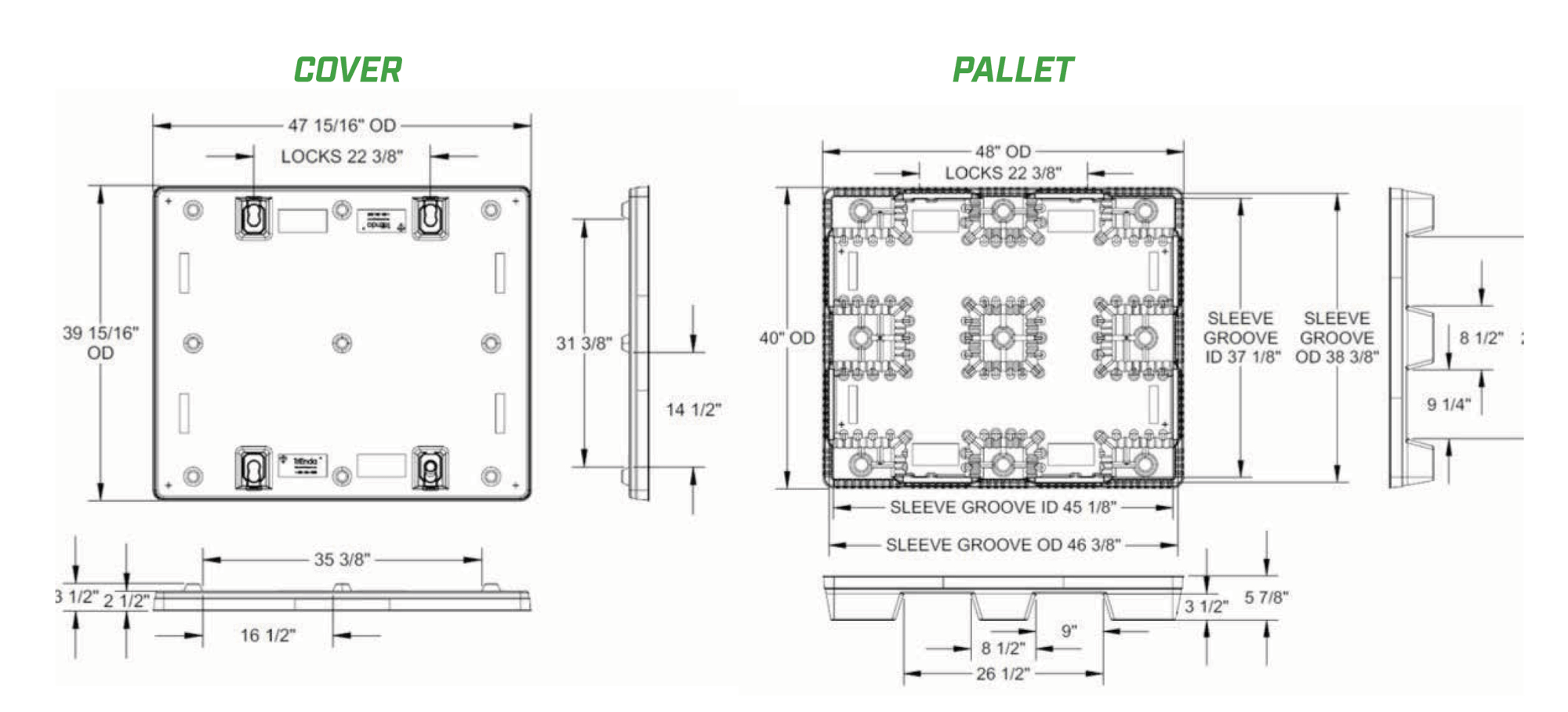

VanPack 40x48

Features:

- Peanut lock provides unit security and eliminates need for stretch wrap or banding

- Interlocking pallet and cover for secure stacking

- Large leg footprint

- Lower cost alternative vs. rigid alternatives

- Quick and easy set-up

Options:

- With or without peanut lock

- Wide range of stripe colors

- One or multiple stripes in 48" direction

- Leg drain holes

- Custom logos

Advantages

- Fully recyclable

- ISPM 15 exempt

- Long service life

- Pallet buy back guarantee

- Easy clean & sanitary

- Weather resistant

- Impact resistant

- 4-way forklift entry