Battery Tray Solutions That Move at EV Speed

Reusable, drop-tested, and fully recyclable systems for EV cells and packs. Designed for safety, cost efficiency, and rapid deployment across your plant and your supply chain.

Battery Tray Solutions

Vantage Plastics engineers a complete family of battery trays for every move your operation makes.

- In-plant transport trays cut weight compared to steel, improve fuel efficiency, and are built to handle heavy loads (up to 6,000 lb) with confidence.

- Direct-to-consumer clamshells eliminate expendables, wash and reuse easily, and are CFR drop-tested for real-world protection.

- Between-plant options include collapsible unit loads that stack down for return trips and vibration-isolating trays with sonic-welded isolators that stabilize cells in transit.

- For racked storage and moves, our rack-compatible system integrates fire-retardant walls and fork-truck resistance.

Every format is purpose-built with dimensions, weights, and payloads dialed to EV programs: from a 94 × 70 × 21 inch in-plant tray at roughly 270 lb, to a 51 × 36 × 18 inch clamshell around 49 lb rated for about 2,000 lb, to a 57 × 50 × 50 inch collapsible unit near 200 lb that carries about 4,000 lb. Vibration-isolating sets are optimized for high pack counts per unit and stack three high to maximize cubic efficiency. All are recyclable at end of life through our circular-economy partner, Edge Materials Management. Bring us your part geometry and packaging constraints and we will tune the right combination of material, structure, and handling features.

Fire-Retardant Material Advantage

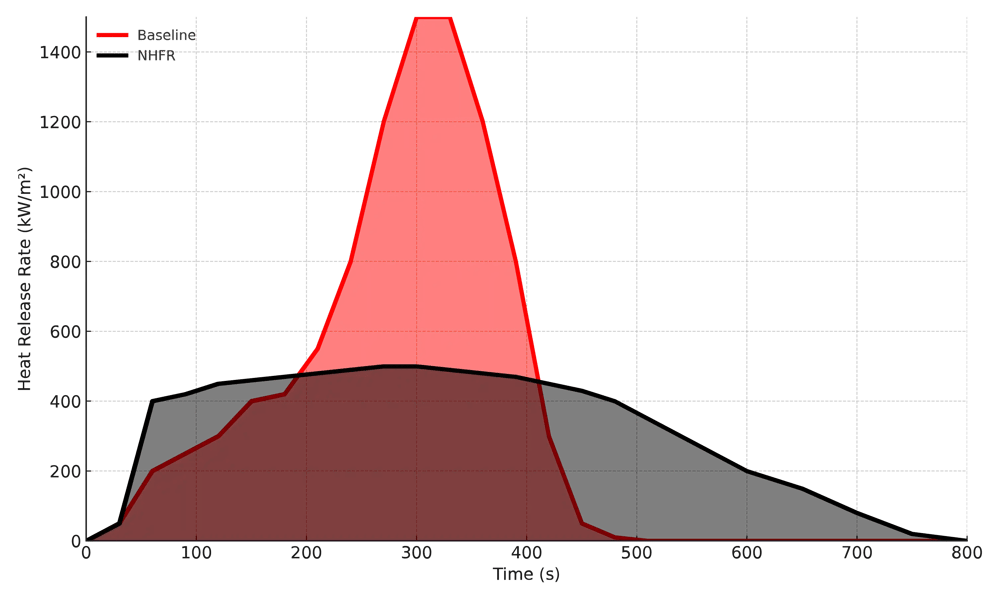

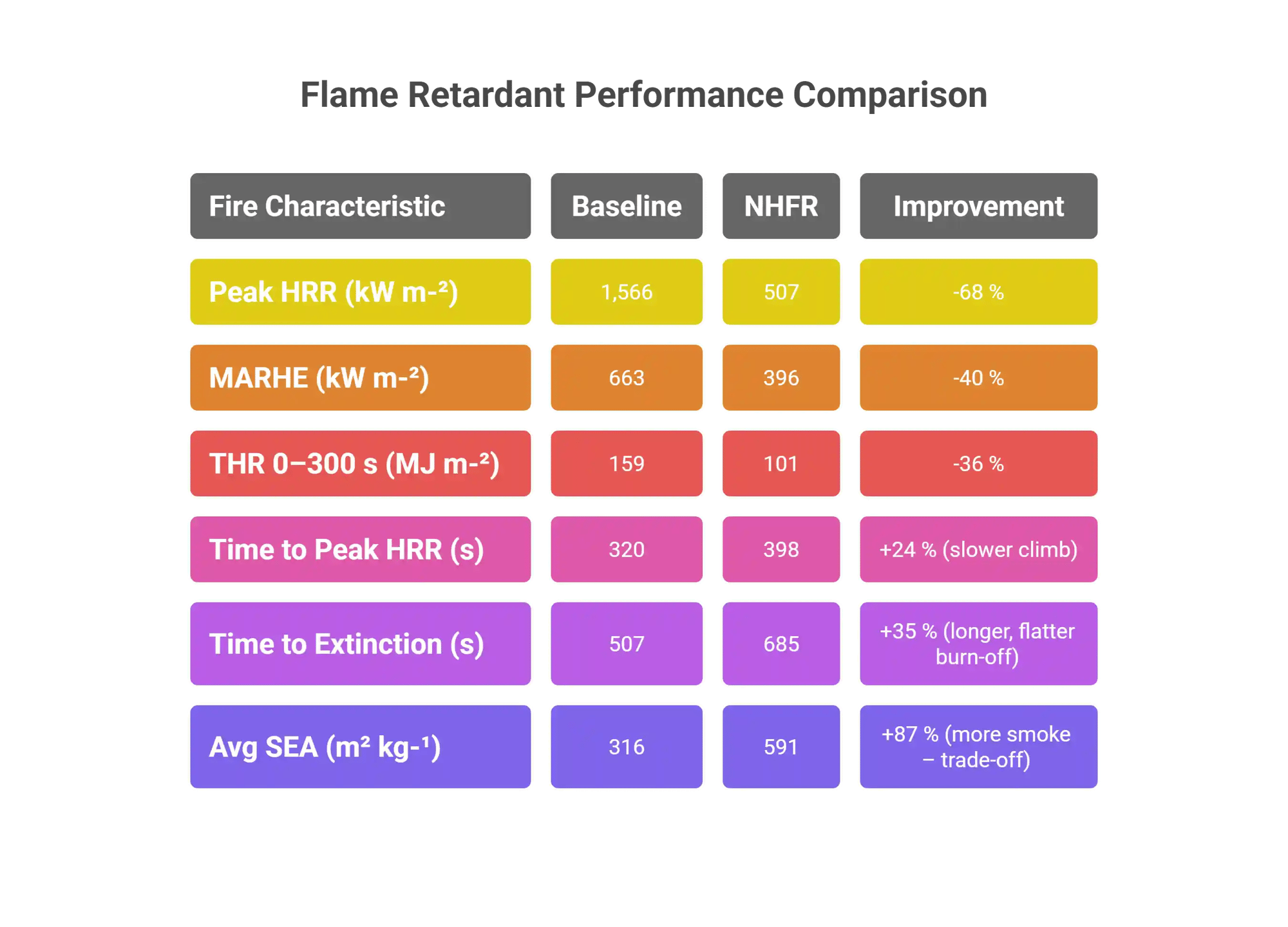

Safety starts at the material level. Our NHFR (Non-halogen Flame Retardant) specification meets ASTM E-1354 (oxygen consumption calorimetry) while maintaining balanced mechanical performance. This formulation is FDA Compliant for relevant applications, slows ignition and heat release, and resists melt-through so first responders and operators gain critical time during an incident.

Our NHFR engineering focus is to hit the sweet spot that preserves strength, durability, and service life without sacrificing compliance or flame retardance. Pair that with thoughtful wall design, reinforced edges, and drop-tested geometries, and you get battery packaging that protects people and product while staying efficient to manufacture, ship, clean, and recycle.