Thermoformed plastic, a widely used material in various industries, has raised concerns regarding...

Plastics Mythbusters: Sustainable Plastics, Recycling, and Returnable Packaging

At Vantage Plastics, we work with OEMs, manufacturers, and supply chain teams every day who want to do the right thing on sustainability, but are stuck navigating a lot of noise. Plastics are often treated as one story with one ending. In reality, plastics can be single-use and wasteful, or they can be engineered as durable, returnable assets that cycle through a supply chain for years, then get recycled into feedstock and used again.

This article is our “Plastics Mythbusters” take on the misconceptions we hear most often. We will keep it straightforward, specific, and grounded in how industrial plastics are actually designed, manufactured, recovered, and recycled.

What “sustainable plastics manufacturing” means to us

In manufacturing, sustainability is not a label. It is a set of outcomes you can measure over time:

- Long service life and reuse cycles (How many trips, how many years, how many rotations through production?)

- Damage prevention (Does the packaging protect high-value parts and reduce scrap and rework?)

- Material efficiency (Can we reduce thickness or weight while maintaining performance?)

- Transport efficiency (Can we improve pack density and reduce trucks?)

- End-of-life recovery (Is there a real, reliable path to recycle the product when it is done?)

The last one matters more than most people think. Many things are technically recyclable. Far fewer have a defined recovery plan that makes recycling predictable in the real world.

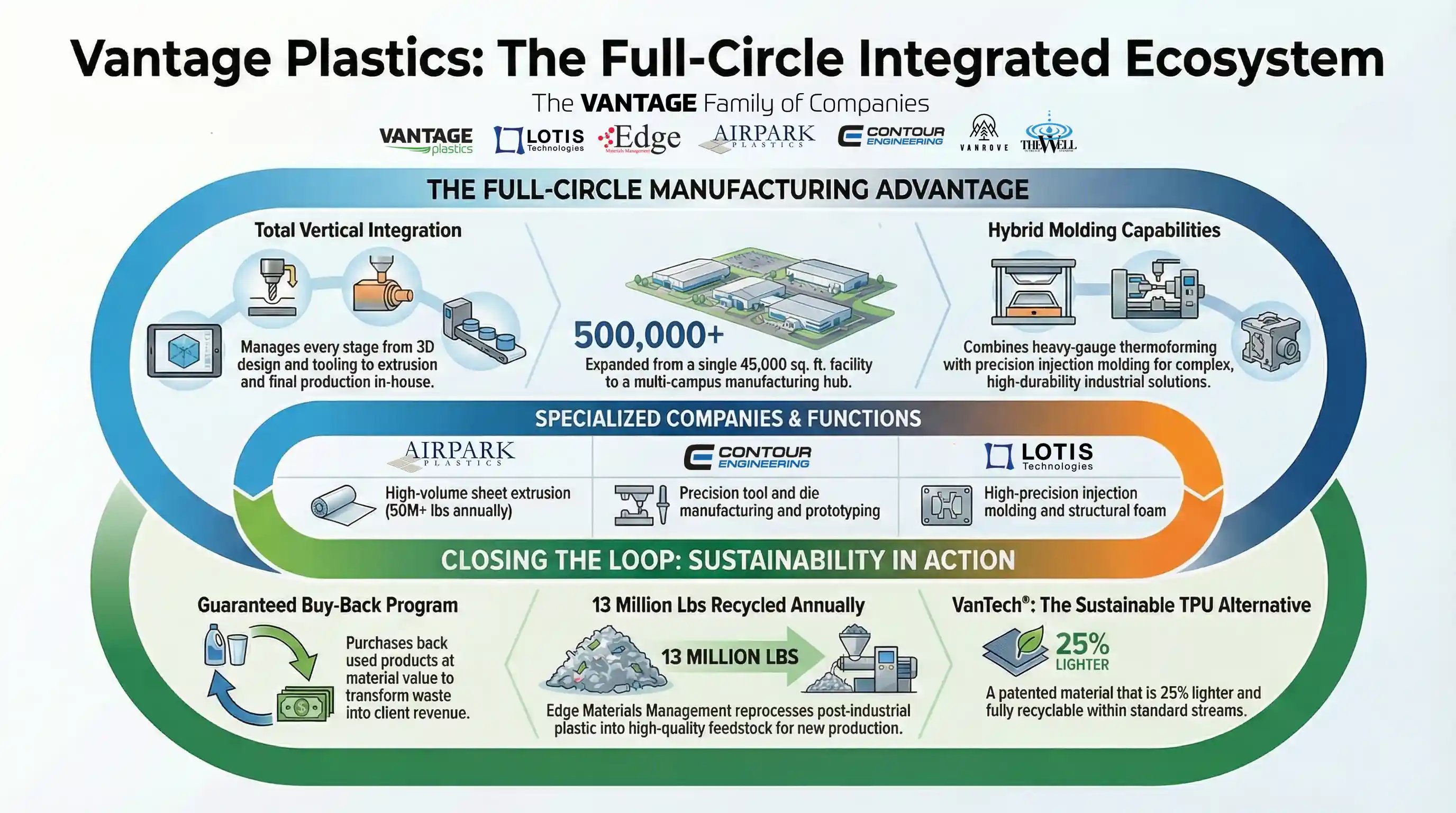

That is why we built our model around vertical integration and “full circle production,” including a guaranteed buy-back program powered by our in-house recycling company, Edge Materials Management.

Myth vs Fact: Plastics Sustainability in the Real World

Myth #1: “All plastics end up in landfills.”

Fact: In industrial programs, plastics can be designed for long service life, then recovered at end of life, especially when buy-back is built into the program.

A big disconnect in the public conversation is that industrial plastics often behave like durable assets, not disposable items. Returnable packaging, trays, dunnage, and pallets can run for years, and when designed correctly, they protect parts better, reduce damage, and reduce the total number of replacements purchased over time.

We also believe the end of a product’s useful life should not be the end of its material value. That is why we back every product we manufacture with a guaranteed buy-back program. When you are done with it, we will purchase it back at material value, and our recycling team at Edge helps reintroduce that material as feedstock.

What we want customers to ask: Is this program designed for reuse, and is there a defined recovery plan when it is done?

Myth #2: “Recycling is mostly about consumer bottles.”

Fact: Post-industrial plastic recycling is a major pathway, and it can be more controllable because incoming material streams are known.

Edge Materials Management is our in-house recycling engine, founded in 2016 in Standish, Michigan, built to keep post-industrial plastics in a true closed loop.

When materials arrive at Edge, the process is operational and disciplined: receive and verify, sort, shred, grind, wash, dry, store in silos, pelletize, and quality check, with the goal of delivering clean, consistent feedstock back into production.

Edge also lists the types of post-industrial streams it regularly processes, including HDPE/HMWPE, multiple PP streams (injection, structural foam, extrusion), ABS, PC/ABS, and EPP foam.

Why this matters: “Recycling” is not one thing. Post-industrial recycling is a proven, scalable route when you have the right controls and infrastructure.

Myth #3: “Recycled plastic is always low quality and inconsistent.”

Fact: Consistency comes from verification, sorting, and process control, not from whether material is virgin or recycled.

Recycled content gets a bad reputation when inputs are mixed, contaminated, or variable. Our approach focuses on controlled streams, verification, and repeatable processing steps. Edge describes converting approved post-industrial streams into high-quality regrind and pellets through a defined workflow, then returning that material as consistent feedstock.

We see sustainability as an engineering discipline. When you treat recycling like manufacturing, you get manufacturing-grade outputs.

Myth #4: “Thermoformed plastics are not recyclable.”

Fact: Many resins commonly used in thermoforming are recyclable, and recovery becomes far more realistic when products are designed around compatible streams.

Thermoforming is versatile because many plastics can be used depending on application requirements. Our team works with materials including ABS, HDPE/HMWPE, HIPS, PP, PC, PETG, PVC, TPO, and others, with selection driven by performance needs like impact strength, heat deflection, forming behavior, and required additives.

Where recyclability often breaks down is design complexity: mixed materials without a sorting path, hard-to-remove components, or assemblies that require teardown. A strong sustainability strategy starts upstream, choosing compatible streams and designing for straightforward recovery.

Myth #5: “Metal or wood is automatically more sustainable than plastic.”

Fact: Sustainability is a lifecycle outcome, not a material stereotype.

In industrial supply chains, the biggest drivers of environmental impact are often practical and measurable:

- How many times something gets reused

- How often it fails and must be replaced

- How much damage it prevents to higher-value parts

- How efficiently it ships (weight and cube)

- Whether it can be recovered and recycled at end of life

We have seen programs where the most responsible choice is a well-designed plastic solution because it reduces damage, improves packing density, lasts longer, and creates a clear end-of-life pathway.

For example, our VanStack load-bearing columns are designed to increase load density and reduce shipping inefficiency, and we share comparative testing metrics such as increased unit load density, reduced starting thickness, and increased tested load capacity in program comparisons.

Myth #6: “Sustainability means sacrificing performance.”

Fact: In many programs, the best sustainability improvements are performance improvements.

One of the most effective sustainability levers is simple: do more with less. Reduce material without reducing performance. Ship more parts per load. Reduce damage. Build products that last.

Our innovations are designed around those outcomes. VanStack is positioned as a density-increasing dunnage solution with benefits like increased parts per tray, fewer trucks needed, reduced tray weight, reduced total material needed, and the ability to recycle columns with the tray at end of life, with no fasteners or adhesive required.

We also work across thermoforming and injection molding through our family of companies, including LOTIS Technologies, which focuses on injection-molded returnable packaging and highlights solutions aimed at part protection, efficiency, and sustainability in demanding environments.

Myth #7: “Closed-loop recycling is too small-scale to matter.”

Fact: Closed-loop programs scale when recycling throughput and manufacturing capacity are aligned.

Closed-loop is only credible if it can handle real volume and consistently turn recovered material into usable feedstock.

Edge states average output of about 60,000 to 70,000 pounds per day and about 600,000 pounds of in-process silo capacity, with throughput depending on material.

On the manufacturing side, AirPark Plastics, our sheet extrusion division, operates five extrusion lines and lists capacity figures including 140,000+ pounds per day and 50,000,000+ pounds per year, supporting high-volume sheet production.

This connection between recycling, extrusion, and forming is what makes “full circle production” practical instead of theoretical.

Three things that actually make a plastic product more sustainable

1) Long service life and repeat use

Returnable packaging changes the sustainability equation because one durable asset can replace many one-time shipments. Long service life reduces replacement purchases, reduces waste, and stabilizes supply chains.

2) Better density and fewer trucks through smarter design

Transport is a major, often overlooked driver of footprint. If we can increase parts per tray, improve stacking, or reduce packaging weight, we can reduce freight and shrink the total system impact. VanStack is designed around these measurable logistics improvements.

3) A real end-of-life pathway that turns products back into feedstock

This is where most programs succeed or fail. We built our guaranteed buy-back program so end-of-life becomes a managed asset instead of a disposal problem, and we built Edge to process post-industrial material into feedstock that can return to production.

Our “full circle” approach across the Vantage family of companies

Sustainability often fails in the handoffs: one supplier makes the part, another handles recovery, and no one owns the loop.

We chose a different model. Our ecosystem connects:

- Industrial recycling through Edge Materials Management

- Plastic sheet extrusion through AirPark Plastics

- Thermoforming through Vantage Plastics

- Injection molding through LOTIS Technologies

We also invest in proprietary materials and innovations. For example, VanTech is positioned as a TPU alternative that delivers performance at reduced weight and cost, and is described as fully recyclable with HDPE streams without special teardown required.

This is how we try to bring clarity to a topic that often gets oversimplified. We do not claim plastic is always the answer. We do believe responsible plastics manufacturing is possible when durability, reuse, and recovery are designed into the system from day one.

Frequently Asked Questions

Is plastic sustainable?

It can be, when it is engineered for long service life, reused over many cycles, and recovered into a defined recycling pathway that turns material back into usable feedstock. Our full circle model is built around that approach, including a guaranteed buy-back program powered by Edge.

What is post-industrial plastic recycling?

Post-industrial recycling processes plastic scrap, off-fall, and obsolete products from manufacturing operations, then converts approved streams into regrind or pellets that can be reused as feedstock. That is the focus of Edge Materials Management.

What plastics does Edge recycle?

Edge lists HDPE/HMWPE, multiple PP streams, ABS, PC/ABS, and EPP foam, and notes other streams may be evaluated on request.

Can Edge handle large volumes?

Yes, we average output of about 60,000 to 70,000 pounds per day and about 600,000 pounds of in-process silo capacity.

What makes a closed-loop manufacturing program work?

A closed loop needs three things working together: a recovery mechanism (like buy-back), a recycling operation with capacity and controls, and manufacturing capacity that can reuse the processed material. Our model connects those steps through Edge, AirPark, and our forming operations.