How to Ensure Regulatory Compliance in Thermoformed and Injection Molded Plastics: ISO, FDA, and...

From Pellets to Pallets: How Injection Molding Works at Lotis Technologies (and How to Design for It)

Why Injection Molding Matters At Lotis

Lotis Technologies is the injection molding powerhouse in the Vantage Plastics family of companies. The team specializes in precision injection molded dunnage, shipping trays, seat pallets, rack dunnage, stacking columns, and other returnable packaging components that protect high value automotive and industrial parts in transit.

Lotis runs multiple high pressure injection molding machines along with a dedicated low pressure structural foam press, which is ideal for larger, lightweight, and very rigid products such as pallets and heavy duty trays.

If you have ever wondered “how does injection molding work” or “how should I design parts for injection molding,” this guide is for you.

Injection Molding In Plain Language

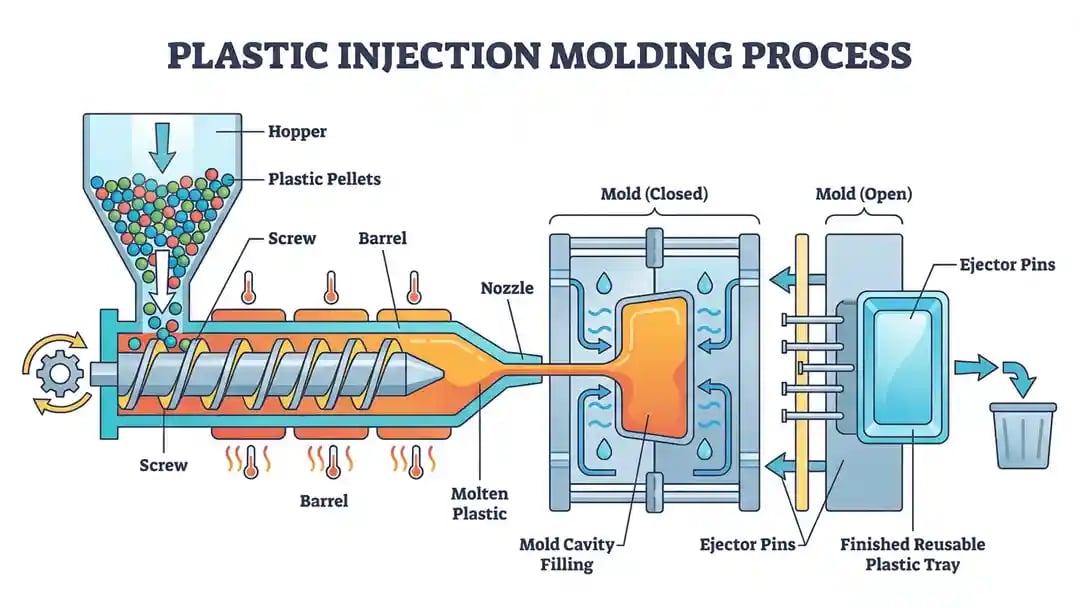

At its simplest, plastic injection molding is a repeatable cycle:

- Plastic pellets go into a hopper.

- The machine heats and mixes the pellets until they are molten.

- The molten plastic is injected into a steel mold at high pressure.

- The plastic cools and solidifies into the shape of the cavity.

- The mold opens, ejector pins push the part out, and the cycle repeats.

You can think of it like a waffle iron that closes, fills, cooks, and opens again, only with far more precise temperature control, pressure control, and tooling.

This basic melt → inject → cool → eject sequence underpins nearly every injection molding application, from a small clip on a wire harness to an entire seat pallet that carries seats into an automotive assembly plant.

A Closer Look Inside The Injection Molding Machine

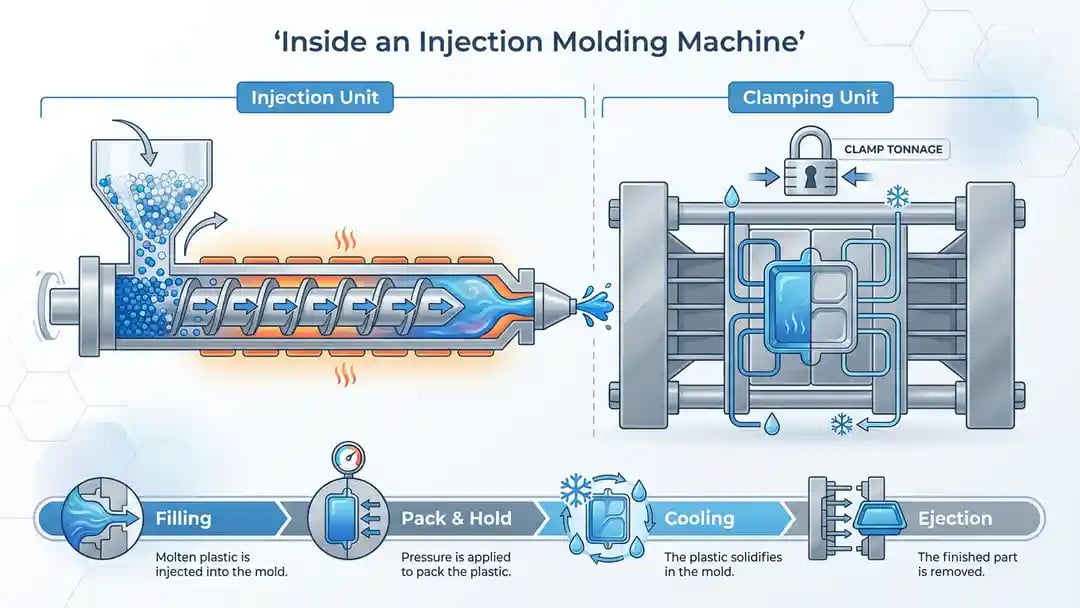

A modern injection molding press at Lotis is built around two main units:

- Injection unit – hopper, barrel, heaters, and a reciprocating screw that melts and meters plastic.

- Clamping unit – stationary and moving platens that hold the mold closed with tons of force while the cavity fills.

Within one production cycle, engineers break the process into tightly controlled phases.

1. Filling

Molten plastic is pushed forward by the screw and enters the mold through the sprue, runners, and gate. The goal is to fill 90 to 98 percent of the cavity at a controlled speed so the flow front is balanced and air can escape through vents.

2. Pack and Hold

Once the cavity is nearly full, the machine switches from velocity control to pressure control. A holding pressure is applied through the gate to “pack out” the part as it shrinks during cooling. This prevents voids, sinks, and short shots and is a key part of scientific molding practice.

The mold is crisscrossed with precision machined cooling channels. Water or oil flows through these channels to remove heat from the plastic until it is solid enough to keep its shape during ejection. Cooling can represent most of the total cycle time, so Lotis engineers work hard on tool design and process optimization to shorten this phase without sacrificing part quality.

4. Ejection

When the part has cooled, the clamp opens and an ejection system pushes the part off the core. Ejector pins, sleeves, air blasts, or lifters may be used depending on the geometry. The mold then closes and the next shot begins.

This controlled cycle allows Lotis Technologies to produce thousands or even millions of identical components with tight tolerances and very low scrap rates.

High Level, Expert View: Scientific And Structural Foam Molding

For engineers and sourcing teams, the real value lies in how the process is controlled and tailored to each application. Lotis brings two key layers of expertise.

Scientific Injection Molding

Scientific, or decoupled, molding is a methodology that uses data and cavity driven process windows rather than trial and error. The cavity is filled to a defined percentage at a set velocity, then the press transitions to optimized pack and hold pressures and times. The result is a robust “recipe” that produces consistent parts even when there are normal variations in material lot, ambient temperature, or machine behavior.

Benefits include:

- More repeatable dimensions and performance.

- Faster troubleshooting when something drifts.

- Lower scrap and more predictable cycle times.

For automotive and industrial customers, this consistency is what keeps lines running and packaging programs on schedule.

Structural Foam Injection Molding At Lotis

Lotis also specializes in structural foam injection molding, a low pressure process where a blowing agent creates a microcellular foam core inside a solid skin. This delivers:

- High stiffness to weight ratio, ideal for large pallets and dunnage.

- Reduced clamp tonnage requirements which can allow larger parts on a given press.

- Less shrink and warpage on thick sections compared with standard solid molding.

When your program calls for big, tough components that are still light enough for ergonomic handling or automated systems, structural foam becomes a powerful option.

How To Design Parts For Injection Molding

Design is where many programs are won or lost. Because Lotis is known for its design expertise, the team often engages early to help customers “design for molding” rather than trying to force a cast, machined, or fabricated concept into a mold.

Here are the fundamentals every engineer and buyer should understand.

1. Keep Wall Thickness Uniform

Uneven wall thickness is one of the fastest ways to introduce sink marks, warpage, and long cycle times.

- Aim for a consistent nominal wall, typically in the 2 to 4 mm range for many engineering thermoplastics, adjustable based on material and part size.

- Step changes should be minimized or blended with tapers and radii.

- Thick functional areas such as mounting pads or bosses should be cored out and supported with ribs rather than left as solid blocks.

Uniform walls let the plastic flow and cool more evenly which keeps parts flatter and reduces residual internal stress.

2. Use Draft Angles And Generous Radii

Since parts are ejected off a steel core, they need draft so they can slide without scuffing.

- Exterior surfaces usually require at least 0.5 to 1 degree of draft.

- Textured surfaces often need 2 degrees or more.

- Interior cores may need slightly more to release cleanly.

Sharp inside corners act as stress concentrators and can trap material flow. Fillets and radii improve strength and flow while reducing the risk of cracking.

3. Design Ribs, Bosses, And Inserts Correctly

Ribs and bosses are critical in automotive trays, seat pallets, and rack dunnage where strength and stiffness are required without unnecessary weight.

- Rib thickness at the base should generally be 40 to 60 percent of the adjoining wall thickness to avoid sink.

- Bosses should follow similar guidelines and can be tied back to walls with supporting ribs.

- Rib height and spacing must balance stiffness, cooling, and flow so that material reaches every extremity of the part.

When metal inserts are needed for threaded connections or wear surfaces, designers must consider proper wall stock around the insert and the right installation method, whether overmolding or post molded insertion.

4. Think About Flow, Gates, And Knit Lines

Where the molten plastic enters the part and how it flows through the cavity are major design decisions.

- Gate types include edge gates, pin gates, fan gates, submarine (tunnel) gates, and more. Each has different effects on shear, cosmetics, and vestige.

- Gate placement should promote even flow and avoid trapping air. Poor venting or long flow lengths can lead to burn marks, shorts, and dimensional variation.

- Areas where two flow fronts meet become knit or weld lines. Critical structural features or cosmetic surfaces should be positioned to avoid weak knit lines or supported with design features and process tuning.

Lotis engineers use flow simulation tools and their real world experience with dunnage, pallets, and trays to make decisions that balance appearance, strength, and mold complexity.

5. Balance Performance, Cost, And Tooling

Good injection molded part design is always a three way conversation:

- Performance – load carrying, impact resistance, chemical exposure, and temperature.

- Cost per piece – driven by cycle time, material choice, and scrap rate.

- Tooling investment – number of cavities, complexity of slides and lifters, and expected program life.

Because Lotis is focused on returnable packaging and durable components, programs often justify more sophisticated tooling that pays back through long life and reduced part damage in the field.

What Working With Lotis Technologies Looks Like

When you bring a project to Lotis Technologies, you are connecting with an integrated team that spans:

- Concept and DFM support.

- Material selection, including structural foam where appropriate.

- Tooling design and build through trusted partners.

- Process development using scientific molding.

- Ongoing production and continuous improvement inside the Vantage Plastics family’s Bay City facility.

For automotive OEMs and Tier 1 suppliers in particular, Lotis understands how packaging fits into the entire supply chain. Solutions are engineered to:

- Protect Class A surfaces and critical features.

- Interface cleanly with automation, conveyors, and robots.

- Stack, nest, and cube efficiently in trucks and warehouses.

- Integrate with thermoformed components, extruded sheet, and recycled content through other Vantage business units.

Key Takeaways: How Injection Molding Works For Your Program

If you are exploring or already using injection molded solutions, keep these points in mind:

- The basic cycle is simple, but consistent quality comes from precise control of fill, pack, hold, and cooling.

- Scientific molding, along with well designed tooling, produces dependable parts from shot to shot and shift to shift.

- Designing for injection molding early in the project prevents expensive changes later and keeps your parts lightweight, strong, and cost effective.

- Lotis Technologies brings deep expertise in both high pressure injection molding and structural foam, tailored to demanding automotive and industrial environments.

When you are ready to talk through a new tray, pallet, or custom component, the Lotis team is ready to walk through your requirements, review your CAD, and show you how the injection molding process can be engineered around your program rather than the other way around.