HOW TOUCHLESS PACKAGING AND HANDS-FREE DISTRIBUTION IMPROVES SUPPLY CHAIN EFFICIENCY

Why Are Reusable Plastic Trays Essential for Vertical Farming Success?

Growing Upward: How Vantage Plastics Is Revolutionizing Vertical Farming

The global vertical farming market is experiencing explosive growth, soaring from USD 13.04 billion in 2025 to an anticipated USD 90.71 billion by 2034 at a remarkable 28.3% CAGR. As urbanization intensifies, 82% of North Americans will be city dwellers by 2050, land scarcity and soil degradation have rendered traditional agriculture increasingly untenable. Indoor farming, powered by hydroponic systems, offers a solution: it uses up to 90% less water than conventional methods, yields 10-15 times more per square foot, and supports 6-12 crop cycles each year. But none of this is possible without one unassuming workhorse: the reusable growing tray.

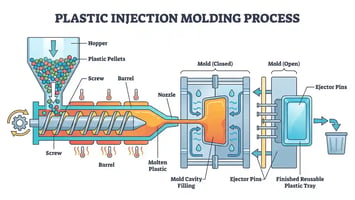

At Vantage Plastics, our integrated capabilities in thermoforming, injection molding, sheet extrusion, and closed-loop recycling through Edge Materials Management uniquely position us to deliver advanced tray solutions for modern vertical farms. By marrying precision engineering with sustainable materials science, we transform trays from simple containers into strategic assets that boost yield, slash costs, and enable automated, AI-driven operations.

Why Reusable Thermoformed Trays Are Essential for Vertical Farming Success

-

Structural Integrity Under Load: Multi-tier systems load trays with 40-50lb of saturated plants. Engineered rib patterns distribute weight evenly, preventing mid-span bow and structural failure over thousands of cycles.

-

Optimized Drainage and Ebb-and-Flow Irrigation: Integrated channel networks ensure uniform nutrient distribution, minimize root rot risk, and support rapid flood-and-drain cycles critical to hydroponic efficiency.

-

Food-Contact Safety and Material Compliance: Thermoformed HDPE meets FDA food-contact regulations, eliminating harmful leachates and making our trays suitable even for pharmaceutical, nutraceutical, and research-grade crops.

-

Automation-Grade Precision: Tight tolerances (±0.005″) allow seamless integration with robotic conveyors, vision-system fiducials, and RFID tracking for real-time inventory management and digital-twin simulations.

-

Superior Longevity and Lower Total Cost of Ownership: Our trays outlast single-use alternatives by 5-10 years, delivering 60-70% lower cost of ownership over multiple crop cycles while reducing waste streams and replacement downtime.

AI, Automation, and Sustainability Driving Tray Innovation

Modern vertical farms are smart farms. Embedded IoT sensors in trays monitor moisture, nutrient concentrations, and plant health, feeding data to AI engines that optimize lighting, climate, and irrigation in real time. RFID integration and machine-vision-ready fiducials enable autonomous stocking, harvesting, and quality-control workflows. Vantage Plastics designs trays with standardized footprints for global conveyor compatibility, ensuring flange-free surfaces that glide through pick-and-place lines without jams.

Sustainability underpins every design choice. Edge Materials Management processes over 12 million pounds of plastic annually in a closed-loop system that buys back and recycles used trays into new ones. This local recycling reduces carbon emissions and guarantees traceable recycled content that still meets stringent food-safety standards.

Tailored Solutions for Key Crops

Leafy Greens and Herbs dominate hydroponics, claiming 45% of the North American market. Our trays can maximize plant spacing and airflow, can incorporate root-barrier zones to prevent cross-contamination, and can feature ergonomic harvest ports for minimal crop disturbance.

Strawberries and Berries require complex cavity geometries to cradle fruit and channel runoff. We use advanced CAD and finite-element analysis to tailor tray cavities, balancing delicate fruit support with optimum drainage under high-density planting schemes.

Emerging segments, pharmaceuticals, nutraceuticals, and laboratory research, place the highest demands on material purity and traceability. Vantage Plastics’ ISO 9001-certified processes and recycled content meet these exacting standards, enabling controlled-environment agriculture for high-value compounds.

Economic and Operational Impact

By adopting reusable thermoformed trays, growers can:

- Reduce Water Use by Up to 90% through efficient recirculation

- Cut Labor Costs by 3-4X via automated handling and standardized tray footprints

- Optimize Space Utilization with 10:1 nesting ratios that shrink storage volume by 90%

- Stabilize Revenue Streams with consistent, year-round production and predictable yields

- Mitigate Climate and Pest Risks in enclosed environments

These advantages translate into faster breakeven, stronger margins, and resilient supply chains for commercial vertical farms, urban agriculture startups, and research institutions alike.

Why Choose Vantage Plastics?

Vantage Plastics offers a vertically integrated manufacturing ecosystem that no competitor can match. From thermoforming and injection molding to sheet extrusion and closed-loop recycling, we handle every step under ISO-certified quality controls. Our 29 years of manufacturing expertise and recognition as GM Supplier of the Year 2023 underscore our commitment to excellence. By partnering with Vantage Plastics, growers tap into:

- Cutting-edge materials science for durable, high-performance trays

- IIOT-ready designs that drive smart, automated growing

- Circular-economy manufacturing that minimizes environmental impact

- Custom engineering support for crop-specific tray solutions

The vertical farming revolution is growing upward—and reusable thermoformed trays are at its foundation. To power your next harvest with sustainable efficiency and AI-driven precision, contact Vantage Plastics’ engineering team for a tailored consultation.