7 REASONS BUSINESSES SHOULD IMMEDIATELY INVESTIGATE CHANGING FROM THE USE OF WOOD PALLETS TO...

The Evolution of Thermoforming: From Parkesine to Modern Innovation

The history of thermoforming plastic is rich and spans over a century, marked by significant advancements and innovations. Thermoforming is a relatively simple process: sheets of plastic are heated until they become soft and flexible, then are formed over a mold, and cooled to create various shapes. This method has been fundamental in manufacturing a wide range of plastic products. This process is used all over the world to produce products we use every day, but do you know how it all started?

The history of thermoforming plastic is rich and spans over a century, marked by significant advancements and innovations. Thermoforming is a relatively simple process: sheets of plastic are heated until they become soft and flexible, then are formed over a mold, and cooled to create various shapes. This method has been fundamental in manufacturing a wide range of plastic products. This process is used all over the world to produce products we use every day, but do you know how it all started?

The early beginnings and 19th century developments of thermoforming plastic are marked by groundbreaking discoveries and innovations, particularly in the creation and manipulation of early forms of plastics.

Creation of Celluloid

The journey of modern plastics and thermoforming began with Alexander Parkes, who invented a material known as Parkesine in 1855. Parkesine was made from cellulose treated with a mixture of solvents and nitric acid. It was initially used for waterproofing fabrics. This innovation laid the groundwork for the development of plastics as we know them today.

John Wesley Hyatt acquired the Parkesine patent and began experimenting with cellulose nitrate to create a harder substance that could potentially replace expensive materials like ivory. His significant contribution was the addition of camphor to cellulose nitrate, resulting in a harder material.

John Wesley Hyatt acquired the Parkesine patent and began experimenting with cellulose nitrate to create a harder substance that could potentially replace expensive materials like ivory. His significant contribution was the addition of camphor to cellulose nitrate, resulting in a harder material.

First Thermoforming Method: Hyatt's method of applying steam heat and pressure using steel molds to shape this material can be seen as the earliest form of thermoforming. He used this process to create various everyday items like toys and bottles, pioneering the use of plastics for manufacturing consumer goods. Hyatt is most famously credited with creating the modern billiard ball and the first injection molding machine.

Significance in the Development of Plastic Technology

Hyatt's experiments and the creation of this early form of plastic marked the foundational steps towards modern thermoforming techniques. His work demonstrated the potential of plastics as versatile materials for a wide range of applications. These early developments in manipulating cellulose nitrate were crucial in setting the stage for future innovations in plastic manufacturing and thermoforming techniques.

The mid-20th century, particularly the period around World War II, was a crucial era for the development of thermoforming technology. This period saw significant advancements driven by the demands of the war, leading to innovations that would shape the future of plastic manufacturing.

Pre-War Developments and Innovations.jpg?width=226&height=223&name=download%20(3).jpg)

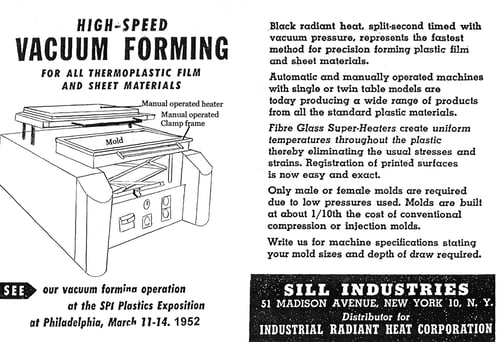

The invention of the roll-fed thermoforming machine by C.B. Strauch in 1938 marked a significant advancement. This machine allowed plastic webbing to be heated, formed over a mold (initially wooden), and then trimmed. It was used for a variety of products including ice cube trays and plastic tips for cigarettes. This innovation was a precursor to more advanced thermoforming techniques and machines.

World War II Contributions

The need for lightweight and durable materials during World War II accelerated the development of thermoforming techniques. The aerospace industry utilized these methods to produce components like aircraft cockpits. This was a period of rapid innovation, focusing on materials like acrylic, which were essential for making planes lighter and faster. The period also saw significant improvements in mold design and the use of vacuum pressure in the thermoforming process. These advancements improved the accuracy and speed of production, which were vital for wartime manufacturing requirements.

Post-War Expansion and Advancements

After the war, the economic boom led to the continued advancement and application of thermoforming. The demand for consumer goods saw thermoformed plastics being used in a wider range of products, from bathtubs made of acrylic to PVC lining for home refrigerators.

The 1950s witnessed the introduction of a variety of thermoformed plastics in different colors and designs. The improvements in vacuum forming allowed for more intricate details in products, leading to a diverse array of items that were characteristic of the "mid-century modern" aesthetic.

Thermoforming Today

The industry has evolved dramatically, with thermoforming now being much faster and producing higher quality plastic packaging. Modern techniques include the use of heat, vacuum, and pressure on automated machines to transform plastic sheets into three-dimensional shapes.

The global thermoforming plastic market has experienced significant growth in recent years. As of 2023, the market value has been reported at approximately $48.71 billion, with a compound annual growth rate (CAGR) of 7.1% from the previous year. This growth trend is expected to continue, projecting the market to reach around $61.97 billion by 2027.

The market's expansion can be attributed to various factors, including technological advancements, increasing demand for consumer durables, and the versatility of thermoforming plastics in a wide range of applications. These plastics are used in numerous industries such as healthcare and medical, food packaging, electrical and electronics, automotive packaging, and more, highlighting their extensive utility.

The thermoforming industry continues to evolve, focusing on sustainability, advancements in materials and technology, and expanding applications across different sectors. The drive for eco-friendly practices and innovative designs is likely to shape the future of this dynamic industry.

Vantage Plastics stands at the cutting edge of thermoforming's future, propelled by our relentless innovation and adept integration of the latest advancements. By embracing advanced software for design precision, adopting automation for efficiency, and prioritizing sustainable materials, we lead the industry towards a more sustainable, efficient, and responsive manufacturing landscape. Our focus on custom and eco-friendly solutions demonstrates our commitment to advancing thermoforming technologies, ensuring Vantage Plastics remains a key player in shaping the future of plastics manufacturing.

Sources:

https://www.rohrer.com/blog/what-is-thermoforming-how-did-plastic-packaging-get-its-start/

https://advancedplastiform.com/the-origins-of-thermoforming/