How to Ensure Regulatory Compliance in Thermoformed and Injection Molded Plastics: ISO, FDA, and...

Sustainable Packaging That Works

Sustainable Packaging That Works

Solving the Challenges of Cold Chain Distribution Without Compromising Performance or the Planet

Introduction: A Critical Inflection Point in Food Distribution

The global wholesale food distribution industry is immense, driving more than $990 billion in annual revenue in the U.S. alone and supporting every part of the food ecosystem—from farm to fork, processors to restaurants, retailers to institutions.

Yet, as this sector grows, so do the environmental implications of the systems that support it—especially packaging. Food distributors operate under intense pressure to reduce waste, meet regulatory mandates, and respond to a growing consumer demand for sustainable practices. Nowhere is that pressure more visible than in cold chain logistics, where packaging isn’t just about protection—it’s about preservation, compliance, safety, and efficiency.

But creating truly sustainable food packaging that functions under the demanding conditions of real-world distribution is anything but simple. It requires far more than just swapping out materials. It demands a systems-level rethink.

Section 1: The Realities of Sustainable Packaging in Food Distribution

Food packaging is both a necessity and a liability. While it protects, preserves, and presents perishable products, it also generates substantial environmental impact—through material use, waste, carbon footprint, and end-of-life challenges.

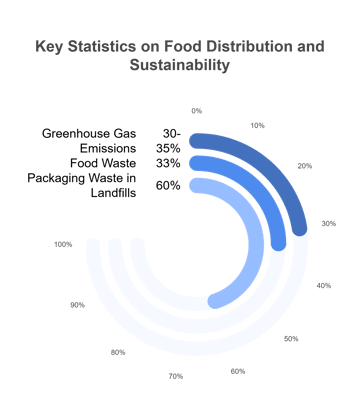

A Few Numbers That Tell the Story:

- The U.S. food system is responsible for 30–35% of total greenhouse gas emissions.

- One-third of all food produced is wasted—often due to spoilage linked to packaging failures.

- Packaging materials make up over 60% of food-related waste in landfills.

- Regulations are intensifying globally: the EU, Canada, and California have implemented or are planning legislation to restrict single-use plastics, require recycled content, and shift toward Extended Producer Responsibility (EPR) models.

Within this context, the promise of eco-friendly logistics packaging is compelling—but complex.

Section 2: Why “Going Green” Isn’t Straightforward

1. Cold Chain Requirements Are Inflexible

In cold and frozen food distribution, temperature-sensitive packaging is essential for product safety, regulatory compliance, and shelf-life extension. The packaging must:

- Maintain thermal insulation from origin to destination.

- Be moisture-resistant and structurally sound in humid or refrigerated environments.

- Stack, nest, or palletize safely without compromising airflow or load integrity.

Traditional solutions—like expanded polystyrene (EPS) or single-use liners—meet these needs, but fail sustainability metrics.

2. Durability vs. Sustainability: A Tough Balancing Act

The packaging must endure rough handling, stacking, vibration, and moisture. While paper-based or compostable materials often appeal visually as "green," they struggle to withstand repeated cycles or exposure to elements. On the other hand, more durable solutions (like hard plastics) are only as sustainable as their design for reuse or recyclability.

3. Food Safety Standards Are Non-Negotiable

Packaging that touches or surrounds food—especially raw proteins or unpackaged produce—must meet FDA or USDA material standards, remain tamper-evident, and prevent contamination. Sustainable alternatives must match these properties while avoiding degradation during repeated use or sanitization.

4. Supply Chain Systems Aren’t Built for Reuse

Reusable packaging sounds ideal—but it only works if the broader system supports it. Return logistics, cleaning protocols, storage, and inventory management must be restructured. For smaller or decentralized distributors, this infrastructure doesn’t yet exist.

5. Sustainability Can’t Be Skin Deep

Customers and regulators are pushing beyond symbolic gestures like “green” logos or minimal recycled content. Stakeholders now demand:

- Lifecycle assessments

- Recyclability at scale

- True material circularity

- ESG-aligned impact metrics

This goes far beyond surface-level claims. A box made of “biodegradable” materials that still ends up in landfill doesn't solve the problem.

6. Cost Sensitivity is Still Very Real

Margins in food distribution are tight. Sustainable packaging must not only perform—it must pencil out. That means lowering total cost of ownership through durability, damage prevention, labor efficiency, and reduced waste disposal.

Section 3: What the Industry Needs in Next-Generation Packaging

True progress in sustainable food packaging—especially in cold chain systems—must address multiple overlapping needs. A singular innovation won’t solve the problem. Instead, what’s required is a coordinated, practical redesign based on six foundational principles:

1. Reusability Over Disposability

Design packaging to last—not just one trip, but hundreds. Consider materials that endure harsh conditions, repeated sanitization, and heavy handling.

2. Material Circularity

Build packaging from recycled content—and ensure it can be reclaimed and remanufactured at end-of-life.

3. Modular & Stackable Designs

Enable efficient cube optimization, palletization, and return logistics. Stackable totes, interlocking lids, and collapsible bins reduce empty freight and storage inefficiencies.

4. Cold Chain Compatibility

Maintain insulation, airflow, and drainage properties critical for temperature control and perishability.

5. Smart Integration

Incorporate RFID, QR codes, or embedded sensors to enable real-time tracking, condition monitoring, and digital traceability.

6. Real ROI

Support measurable outcomes—waste diversion, CO₂ reduction, food loss prevention—that align with ESG goals and customer values.

Section 4: Case Scenarios in Sustainable Packaging Design

To illustrate how these principles come together, consider a few real-world packaging innovations increasingly adopted across food logistics:

✅ Insulated Twin-Sheet Trays

Heavy-gauge thermoformed trays with internal air pockets or foam cores maintain product temperatures during transit—without the use of EPS foam or gel packs. Perfect for meat, dairy, or meal kits.

✅ Reusable Nestable Totes

Common in produce and bakery distribution, these stackable containers feature venting, ergonomic grips, and barcode compatibility. When nested empty, they reduce return volume by up to 70%.

✅ Smart RFID-Embedded Pallets

Used to track goods across multiple stops, reduce loss, and monitor cold chain integrity. Smart pallets align with FSMA traceability rules and food defense protocols.

✅ Returnable Pallet Cover Systems

Interlocking, durable plastic covers that eliminate stretch wrap—cutting down on plastic film waste while providing better load stability and sanitation.

Each of these solutions embodies a systems mindset—not just greener materials, but better design, longer lifecycles, and logistical harmony.

Section 5: The Path Forward — From Intention to Implementation

Every food distributor today faces a common crossroads: How to align their operations with sustainability without losing performance or profitability.

That doesn’t mean every distributor must build a circular economy from scratch. But it does mean choosing partners who can help design and deliver packaging solutions that work in the real world.

Call to Action: Where Vantage Plastics Fits In

Vantage Plastics is one such partner.

With nearly three decades of expertise in thermoforming and injection molding, a vertically integrated operation, and a closed-loop recycling affiliate (Edge Materials Management), Vantage helps food distributors transition from single-use to circular packaging systems—without compromising performance, safety, or cold chain efficiency.

They specialize in:

- Custom packaging design for cold and ambient food products

- Reusable totes, trays, and pallet covers

- RFID-ready packaging and automation-friendly designs

- On-site recycling, reclaim, and reprocessing services

- Proprietary materials (like VanTech®) engineered for insulation and durability

If you’re a food distributor, packaging engineer, or sustainability officer looking to reduce waste while improving logistics and resilience, now is the time to assess your packaging systems.

🔄 Let’s Talk Sustainable Packaging That Works

Contact Vantage Plastics today to explore custom sustainable packaging options.

Together, we can design packaging that protects what matters—your products, your brand, and the planet.