Sustainable Packaging That Works Solving the Challenges of Cold Chain Distribution Without...

Reshoring American Manufacturing for Living‑Wage Jobs

Why Bringing Manufacturing Home Matters – and How Vantage Plastics Is Ready to Lead the Charge

Picture this: it’s 1985 and a 30‑year‑old high‑school grad clocks out after another shift on the thermoforming line. The pay is solid, the benefits are predictable, and the path to a comfortable life—first home, family vacation, maybe a fishing boat—feels almost automatic. Fast‑forward forty years and that same 30‑year‑old is more likely to be juggling gig work, rent that keeps creeping up, and student‑loan bills that don’t.

The difference? We moved an entire ladder of opportunity offshore.

At Vantage Plastics we believe it’s time to rebuild that ladder—right here at home. Reshoring isn’t just a buzzword; it’s a chance to lift American workers to the next level of growth, learning, and living wages while strengthening supply chains and shrinking environmental footprints. Here’s why it matters—and how we’re already rolling up our sleeves.

Four Decades of Drift

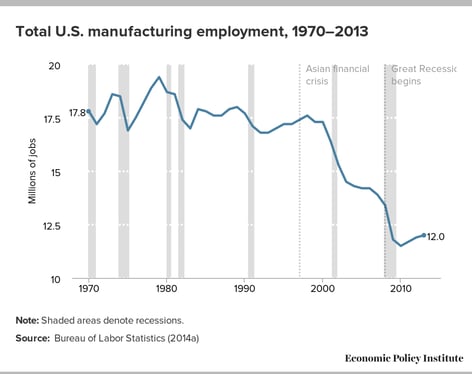

- 5 million fewer U.S. manufacturing jobs since the mid‑1980s

- Real wages for non‑college workers have barely budged in that time

- Home‑ownership for under‑35s has dropped several percentage points

- Young adults now marry and start families 5–6 years later than their parents did

Behind every data point is a person whose best shot at the middle class quietly vanished when the factory lights dimmed. Communities lost tax bases, schools lost funding, and entire regions were left asking, “What’s next?”

Why Reshoring Changes Everything

- Living‑Wage Careers, Not Just Jobs

Advanced U.S. factories pay a wage premium—especially when employers commit to continuous up‑skilling. When production stays stateside, paychecks stay in the community. - Shorter Supply Chains, Smarter Planet

Domestic production slashes transit emissions and gives companies real‑time control over quality and inventory. That’s sustainability and resilience in one package. - Innovation on Tap

Co‑locating design, tooling, AI‑driven automation, and production sparks faster R&D cycles. Ideas become products—and patents—at lightning speed. - Stronger Communities

A vibrant plant anchors local diners, hardware stores, and Little League teams. Bring back the plant and you revive the whole Main Street ecosystem.

How Vantage Plastics Is Already Reshoring the Future

Advanced Manufacturing, Right Here in Michigan - Our Bay City and Standish campuses thermoform and injection‑mold millions of high‑performance parts each year—everything from food‑safe dunnage to proprietary VanTech® packaging. Automated cells and AI‑assisted quality checks push productivity sky‑high without exporting opportunity overseas.

Circular Economy in Our Own Backyard - Through Edge Materials Management we recycle post‑industrial plastics into fresh raw material. AirPark Plastics then extrudes sheet that feeds straight back into our forming presses. Fewer imports, less waste, tighter loop.

Training That Turns Jobs into Careers - Our hands‑on, three‑day training program brings new teammates up to speed on tooling, robotics, and safety. Pair that with cross‑training and tuition assistance and you get a pipeline of problem‑solvers ready for Industry 4.0.

Living‑Wage Commitment - A paycheck should cover more than the basics. We benchmark our compensation to ensure employees can afford housing, health care, and a weekend up north with the family—because growth and learning mean little without the means to live well.

What We’re Asking of Partners, Policymakers, and Peers

- Choose domestic sourcing whenever technically feasible. Every PO is a vote.

- Invest in workforce development. Apprenticeships, community‑college partnerships, and in‑plant up‑skilling keep talent pipelines flowing.

- Leverage smart automation, not to replace people, but to elevate them—think cobots that handle repetitive tasks while operators master data analytics and maintenance.

- Champion stable, pro‑manufacturing policy—from targeted tax incentives to robust trade enforcement that levels the playing field.

Let’s Climb the Ladder—Together

For forty years too many Americans have been asked to sprint up an escalator that’s moving down. Reshoring manufacturing places that escalator in reverse—turning hard work into upward motion once again.

At Vantage Plastics we’ve proven that innovation, responsibility, and friendliness aren’t mutually exclusive—they’re the secret sauce of American manufacturing done right. Whether you need thermoformed solutions, turnkey recycling loops, or a partner who treats people as our greatest asset, we’re ready.

Ready to bring your production home?

Let’s talk. Because when we build here, we all rise.