7 Ways Plastics Have Revolutionized the Medical Industry

While plastics are synthetic and processed, and can have a negative impact on the environment and sea life, it would be unfair to not recognize the vast technological developments and improvements to the quality of life of millions worldwide that can be directly attributed to plastics. These improvements span many industries, but today we’re focusing on one that has likely touched us all very personally: the medical industry.

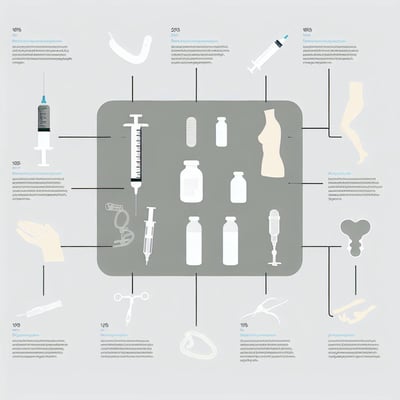

1. VERSATILITY

Medical plastic has a great deal of applications in health care, from the obvious to the unexpected. Disposable medical products like bed pans, inhalation masks and IV tubes have shifted from other materials to plastic in recent decades. Today, plastic is used in pill casings and several kinds of internal implants, from catheters to joint replacements. Most of what you see in a modern hospital room is made of some form of plastic.

2. EASY STERILIZATION

Medical equipment like surgical tools are ideal for one-time use when made of plastic. The spread of dangerous infections and diseases can be prevented by simply disposing of single-use tools after a procedure is finished. However, there are also special plastics used in medical devices with antimicrobial surfaces. Such surfaces are highly effective at both repelling and killing dangerous bacteria, even if they aren’t regularly sterilized.

3. GREATER SAFETY

Since medical plastic is shatter-proof and non-permeable, it is a great solution for safely transporting biohazardous materials. The safe removal of medical waste helps prevent the spread of dangerous pathogens. Medical plastic is also used in tamper-proof caps, ensuring that no foul play is present in a patient’s pharmaceuticals.

4. IMPROVED QUALITY OF LIFE

Medical grade plastics have also helped to make the lives of amputees more comfortable. Since plastic can be highly personalized thanks to injection molding, a patient can receive a lightweight, durable prosthetic. Many plastics are also hypoallergenic, so patients with allergies to traditional medical materials like latex are at a lower risk of reaction during treatment.

5. COST-EFFECTIVE

The wide range of applications, low manufacturing costs and longevity of plastic makes it a sought-after investment in modern medicine. Metal and glass equipment is prone to corrosion and shattering, but plastic is resistant to both. Also, while some plastic tools are made for single-use disposal, other equipment is designed to handle repeated sterilizations and last a great deal longer.

6. ENVIRONMENTALLY FRIENDLY

Plastics are recyclable, making them one of the most environmentally sustainable options for medical equipment. It is much easier for health care providers to meet their demanding medical applications and remain environmentally responsible thanks to medical grade plastics.

7. POTENTIAL OF FUTURE INNOVATIONS

The medical plastic innovations currently being researched could provide even greater benefits to the health care industry. 3D printing makes it much easier to create inexpensive, comfortable prosthetics. Researchers are currently testing an injectable plastic that could help gently staunch bleeding due to internal trauma. The possibilities are many and seemingly endless.