Engineering

Top Level Engineers

At Vantage Plastics, a company known for its innovative approach to plastic thermoforming, the engineering team plays a pivotal role. Their expertise and innovative efforts are at the heart of our company's success in providing customized, environmentally conscious solutions to a diverse range of industries.

Vantage Plastics' engineers work closely with their clients to design and develop products that meet specific needs, showcasing their ability to handle a wide range of custom thermoforming projects. This client-centric approach ensures that each solution is tailored to the unique requirements of the project, demonstrating the engineering team's commitment to innovation and excellence.

Engineering High-Performance Automotive Dunnage Solutions

The engineering of effective automotive dunnage solutions is a complex balance of material science, geometric design, and an intimate understanding of the OEM supply chain. At Vantage Plastics and Lotis Technologies, our engineering team thrives on this challenge, collaborating with automotive clients to design and manufacture packaging that is not just a container, but an integral part of the manufacturing process itself.

Material Science and Design for Class A Surface Protection

From a design perspective, engineering class a surface protection packaging is a zero-tolerance endeavor. Our process begins with material selection, where we specify non-abrasive polymers and co-molded materials to eliminate any risk of scuffing or scratching. We then focus on the geometry of the dunnage, designing contact points to minimize surface pressure and creating a perfect, secure fit that prevents micro-vibrations during transit—the primary cause of cosmetic damage.

A Case Study in Engineered Design: Injection Molded Seat Pallets

Our injection molded seat pallets serve as an excellent case study in our engineering-first approach. The design process for these critical components involves:

- Finite Element Analysis (FEA): To simulate load-bearing scenarios and ensure maximum rigidity without over-engineering material usage.

- Ergonomic Integration: Designing features that assist assembly line workers, improving safety and efficiency.

- Robotic Compatibility: Incorporating precise features for seamless integration with automated handling systems.

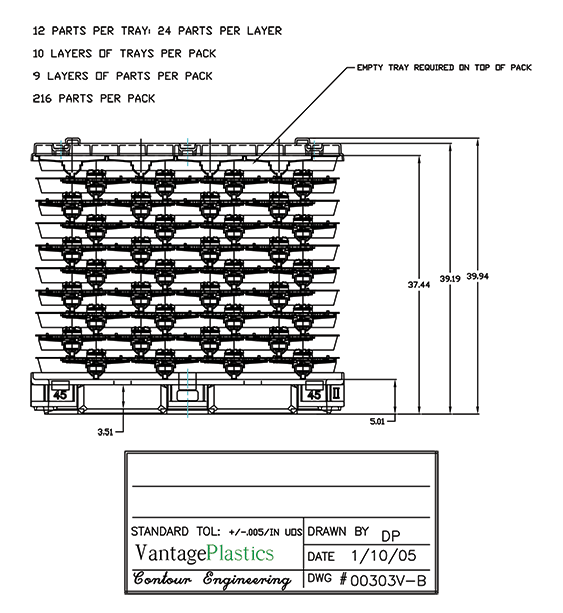

Design for Manufacturing (DFM) for Returnable Packaging

Our commitment to Design for Manufacturing (DFM) is central to how we create effective returnable packaging for OEM parts. We analyze the entire transit loop, from the Tier 1 supplier to the vehicle assembly line. This holistic view allows us to engineer solutions that are not only perfectly protective but also space-efficient (nestable and stackable), cost-effective to manufacture, and durable enough to withstand hundreds of return trips.

Collaborate With Our Engineering Team

Bring us your most challenging component-handling problems. Our engineering team is ready to collaborate with yours to design, prototype, and manufacture a solution that meets your precise technical specifications and integrates flawlessly into your production environment. Contact us to begin the design process.

Engineering & Design Excellence

Our design philosophy is centered on future-proofing our material handling solutions. This foresight is demonstrated through our deep commitment to the circular economy and sustainable manufacturing. The vast majority of our products are designed to be recyclable, reusable, and returnable, helping our clients meet their ESG goals. This dedication to forward-thinking extends to our own operations, where we continuously reinvest in Industry 4.0 technologies like robotics and automation to enhance efficiency and our advanced manufacturing capabilities.

The engineering team at Vantage Plastics represents a synergy of deep technical expertise and innovative problem-solving. Our leadership in heavy-gauge thermoforming, combined with the precision injection molding capabilities of LOTIS Technologies, positions us as a premier industrial packaging supplier. Together, we are continually pushing the boundaries of plastic manufacturing and pioneering advances in closed-loop recycling to build a more efficient and sustainable future.